Getting My Sheroz Earthworks To Work

Getting My Sheroz Earthworks To Work

Blog Article

An Unbiased View of Sheroz Earthworks

Table of ContentsThe 6-Second Trick For Sheroz EarthworksSome Ideas on Sheroz Earthworks You Should KnowSome Ideas on Sheroz Earthworks You Need To KnowUnknown Facts About Sheroz EarthworksSheroz Earthworks Things To Know Before You Get This

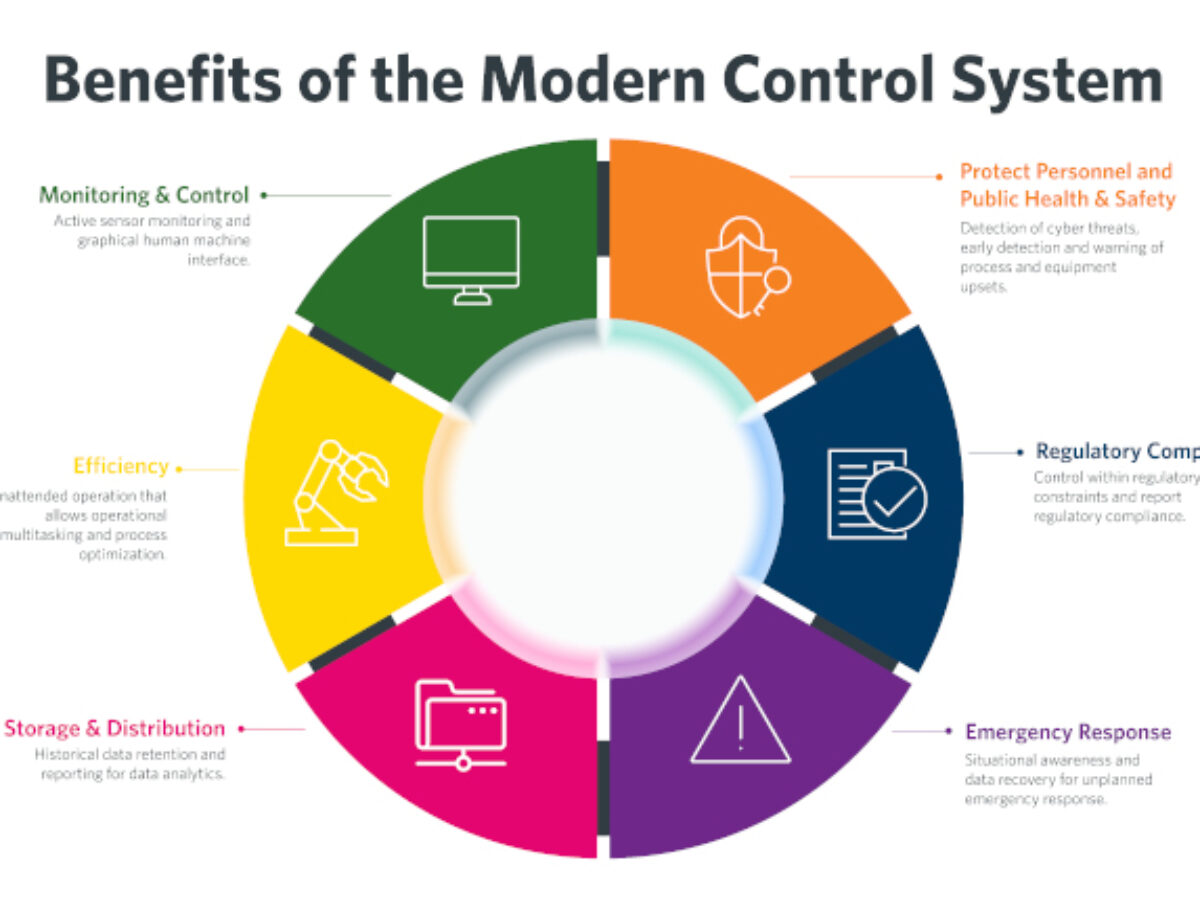

For any kind of earthwork professional, it is crucial to carry out job with quality, accuracy, and on time. Utilizing machine control in job devices enables optimizing the different phases in the earthwork procedure, from preparing to the maintenance stage - trimble gps. The maker control system aids the device driver in achieving the target plane swiftly and quickly

The machine control system guides the driver with centimeter precision. With Xsite PRO 3D, you'll always know precisely just how much to reduce or fill. Your regional Xsite technical assistance can guide you and assist with any problems without visiting the website. Remote assistance conserves time and cash, as it decreases downtime in jobsites.

The Ultimate Guide To Sheroz Earthworks

Extra training and guidelines are constantly offered over remote assistance when required. The earthmoving market has actually used our field-proven services because the very early 1990s. Our system's elements are meticulously designed to hold up against the harsh conditions of construction websites. Comparison of the exact same project carried out using maker control versus the standard method exposes that, usually, the standard method requires 50% even more time to accomplish the exact same task as the technology-assisted technique. https://www.callupcontact.com/b/businessprofile/Sheroz_Earthworks/9261083.

Go into the Xsite equipment control system; it's right here to offer you with a significant advantage when working with earthmoving equipment. Discover how Xsite Device Control can boost your efficiency and make certain job safety! Xsite Machine Control systems can be installed to any kind of excavator from mini excavators to huge mining excavators.

How does maker control work? In 2D systems, the equipment is furnished with calibrated disposition sensors. These sensors are installed on the pre-determined parts of the equipment in excavators the sensing unit are usually installed to the framework, boom (or booms), miner arm and to the fast coupler - trimble gps. By utilizing the data obtained from these sensing units the system can compute the specific setting of the excavators pail tip in significance to a recommendation factor.

The system is extremely easy to learn the basics can be shown in under one hour of training. With Xsite you don't need to fret about finding out all the suggestions and method simultaneously. Added visit homepage training and instructions are always readily available over remote assistance when required. Call your regional Xsite dealer to discover even more! How does the remote support job? A wireless internet link makes it feasible to establish a remote link in between the equipment control system and the service.

Get This Report on Sheroz Earthworks

What type of data formats Xsite systems assistance? Xsite Maker Control systems sustain open common file formats, enabling seamless information circulation from one system to an additional. Supported documents formats: 2D-Maps: DXF Point documents: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Designs: DXF, XML What parts are mounted on my equipment? Relying on your option of system (with or without placing, i.e - trimble tripod parts., 2D or 3D), your machine is furnished with inclination sensing units, a controller device, and a display/operating panel.

Several software and hardware services exist to aid figure out an equipment's existing setting on the earth and contrast it with a wanted layout surfaceand building and construction operators can do even more to leverage the benefits. Device control is making use of various positioning sensors and a display to supply the operator with a recommendation in between the setting of the pail or blade and the target grade.

Depending on the configuration, device control systems can offer the driver with an easy visual guide to pail or blade placement, or can automatically move the blade to grade by speaking with the device's hydraulics - https://www.startus.cc/company/sheroz-earthworks. There are equipment control systems readily available for practically any type of machine: , dozers, excavators, soil and asphalt compactors, scrapers, leaners, grating equipments, and pavers

4 Easy Facts About Sheroz Earthworks Described

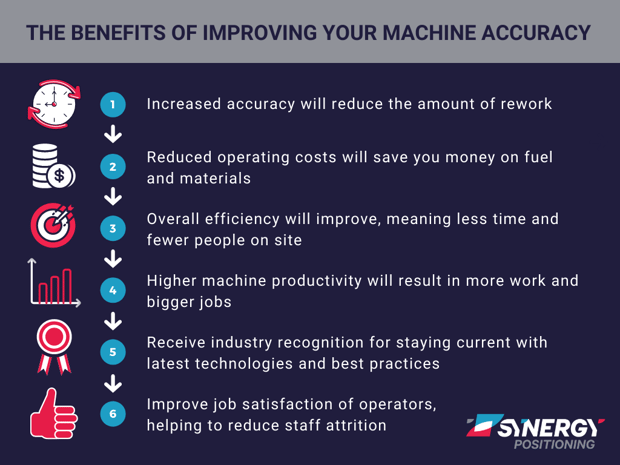

Maker control can also assist boost productivity and decrease total costs. Building and construction tools without machine control will come to be a point of the past and the advantages acquired from it will certainly be numerous.

Trimble maker control systems provide a myriad of benefits to anyone who makes use of earthwork machinery and, at EarthCalc, we can provide you with 3D data for your maker control-enable devices. Uncertain if maker control deserves the price? Consider the complying with reasons you need to consider this option.

Making use of GPS lined up with your 3D style data, these systems practically ensure that you will eliminate or position the appropriate quantity of material at the construction site. On the majority of construction websites, revamp is a common and irritating truth, but with Trimble equipment control, you can eliminate the requirement for rework.

Some Known Questions About Sheroz Earthworks.

Frequently, with Trimble equipment control, you can get rid of excess devices at a particular job website. A job that could have required the usage of three or four pieces of excavating tools currently could need just 2 pieces of devices to complete the very same task in much less time. This enables you to move your equipment to another task site and take care of several work at once.

Report this page